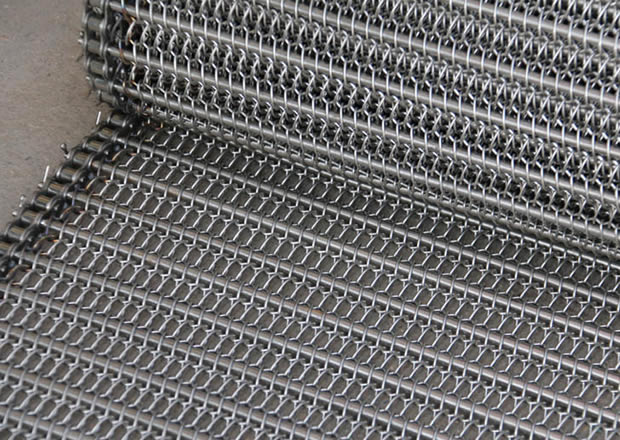

Sprial rod chain driven belt

Sprial rod chain driven belt Sprial rod chain driven belt

Sprial rod chain driven belt Sprial rod chain driven belt

Sprial rod chain driven belt Sprial rod chain driven belt

Sprial rod chain driven belt Sprial rod chain driven belt

Sprial rod chain driven beltMulti-tier spiral conveyor belts for the food industry.

Flexible rod belts are designed primarily for multi-tier spiral conveyors commonly used in food industry. With ability to side flex, belt can also be used for conveyors arranged to go around obstacles.

Whether used on spiral or straight conveyors, the belt is particularly suitable for cooking, cooling or freezing products such as bread, pastry, vegetables, potatoes, fish and meat.

Can also be used for blanching vegetables, proofing dough, drying, baking or pasteurizing.

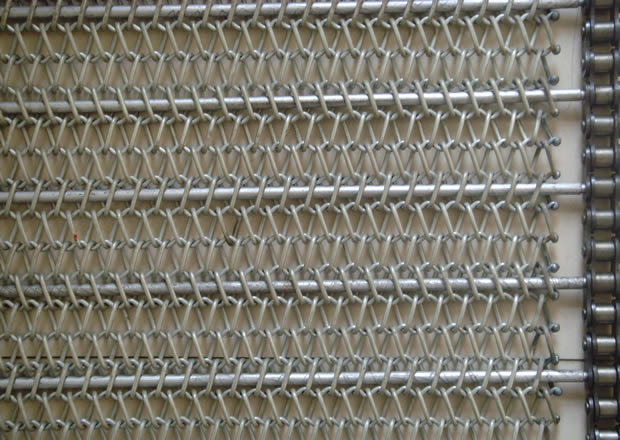

The spiral mesh is usually made of a metal flat wire or a round wire to form flat spiral, which is connected with metal wave wire and welded together at both ends. It has high strength, strong features, strong function, easy to maintain, long service life and good protection for building structure.

Advantages:

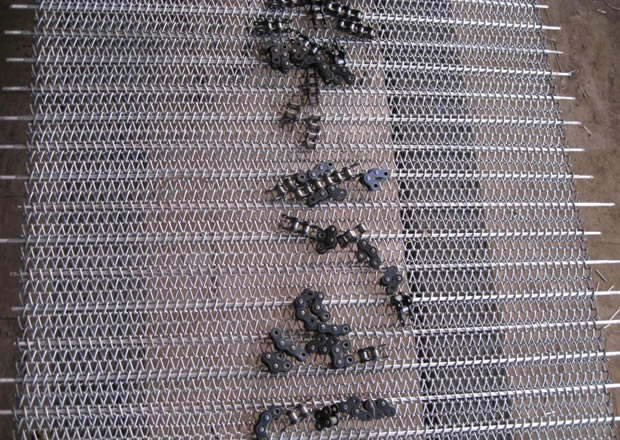

1) Since links are driven by sprockets, reliable and stable running is ensured.

2) Pickling all welded parts and degreasing whole belt are our standard procedure.

3) High-hardness material is used for spiral wire, ensuring higher wear resistance

4) Belt edges are automatically finished to have constant smooth surface.

5) The belts can be used for both straight running and curve to the right or left.

Typical material:

1) SUS 304 (870°C)

2) SUS 201

3) SUS 316L (750°C)

4) SUS 321 (750°C)

5) Various metal material as per your requirements

Typical applications:

1) All kinds of spiral freezer conveyors

2) Cooking

3) Cooling

4) Freezing (bread, pastry, vegetables, potatoes, fish, meat)

5) Blanching vegetables

6) Proofing dough

7) Drying

8) Baking

9) Pasteurizing